Saturday, September 12, 2015

Tuesday, September 1, 2015

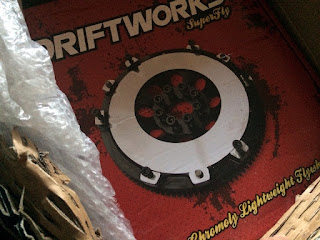

nissan rear main seal, driftworks lightweight chromoly flywheel, exedy sports paddle clutch

Another order from the UK, this time for the driveline on the s13. I'm a big fan of replacing things while you're in there, and this is no exception.

I picked up a single plate paddle clutch by Exedy through Driftworks, and the matching lightweight chromoly flywheel, also from Driftworks. I love the instructions on the back of the clutch. Only in Japan.

This was one of the only clutch and flywheel combinations I could find for the CA18DET. There are many misleading articles and threads online about using SR clutches on the CA, requiring some amount of shimming, likely modification of the bell housing, and many crossing of fingers. I wanted something that bolted on and was guaranteed to work. I even called competition clutches who sold a clutch for a CA, possibly a FWD CA, and wouldn't guarantee it's function, but were fine with me ordering it and letting them know. Nope.

I pulled off the pressure plate and inspected. There was some circumferential scoring but nothing too deep. There was a significant amount of dust covering everything, but seemed normal. All in all it didn't look too bad.

The disc also didn't seem too bad as far as thickness of the pad goes and apparent remaining life. I was still glad to be replacing this while the motor was out though.

The pilot bushing was actually broken, however. I'm not sure if this occurred when I removed the transmission or at some other time in it's life. Either way, it would be replaced.

The flywheel itself seemed to have uniform corrosion on the inside web, as well as a bit of surface rust on the outside where the clutch pressure plate did not contact. Again, not a lot of damage on the working surface of where the clutch disc sat.

As a perfect example of fix it while you're in there, once the flywheel is removed, the rear main seal is exposed and NOW IS THE TIME TO REPLACE IT. I don't care if it's leaking or not. Mine did seem to have a bit of excess oil around it which could have been from environment of the 100k miles it had already traveled, but I was not going to take that chance.

I removed the bracket cover, rear main seal and bushing housing, cleaning off all the old gasket material, pressed the old seal out, installed the new seal, installed the assembly back on the car, and used ample amounts of RTV to seal the new cover.

I laid the clutch pressure plate over the flywheel to figure out which holes the pins needed to be installed for my application. I then very carefully pressed them in with a tapping mallet. They are definitely an interference fit.

At this point I installed the flywheel with the new ARP bolts, I believe for a Ford Pinto, with blue Loctite and the thread fastener ARP goop as instructed, tightening to recommended torque in a star pattern.

Double check your clutch disc is facing the correct direction, in this case with the protruding center section facing aft.

I installed the new pilot bearing, centered the clutch disc with an alignment tool, and bolted down the pressure plate, again in a star pattern with blue Loctite to the correct torque. And of course she's pink.

Monday, August 31, 2015

s13 up-side-down sand & paint

There was no cut & patch or weld & grind on the underside of the repairs. Well, to be fair there was a little grind, but it was nothing compared to the top. Usually if you seal something from one side, that implies it's sealed from the other side.

To finish the repair completely, however, and to be utterly sure the cabin was sealed even though it had already been weld, ground, weld, ground, etc, and then epoxy, sand, paint on the inside, I performed a similar process on the outside.

After taking an excessive amount of photos trying to catch details that will again never be able to be captured, I ground down any excess to the forward repair. This would later be covered with several layers so it was not critical how it looked, probably less so than the inside. If it wasn't apparent already, I will still always opt for doing the correct process, otherwise it won't come out how you want and you will be left wanting and wish you did more.

I then hit the rear of the transmission tunnel where the cuts and tears were.

Repeating what I did on the inside, I bought more epoxy and bonded it to the body. I also filled the mid bearing mount location. You can see clearly when the drive shaft ripped from the car, the mid bearing came with it, including the captured nuts inside the chassis mounts. Even if I were to get some new nuts and weld them back into the mount, they would have to be perfectly aligned with themselves and the chassis for the shaft not to vibrate and turn on an axis relatively inline with that of the transmission and differential. In the current circumstances I did not think this was a likely outcome, and since I needed a new prop shaft anyways, I would opt for a single piece, not requiring a mid bearing.

Once the entire surface was covered with epoxy, I began the electric sanding process with the mouse and velcro pads, then moved on to hand sanding.

The mid bearing mounts came out very smooth just from the epoxy coverage for some reason, and now it was time for the final step to move on from this stage of my life.

I went back with a few layers of thicker underbody paint to make things match. The flash highlights everything so you can see the differences in body, but in normal light, even when touching it, it looks amazing. It looks like an underside of a car.

Before getting out from under the car, I took a few shots of the empty engine bay and the old mounts, which would soon be replaced with driftfreaq mounts. These are similar to the mounts I made for my Datsun. The molds are better, they're not semi-solid, there's a heat shield for the exhaust side, and more importantly, I did not have to make them.

Subscribe to:

Posts (Atom)