What's the first thing you do after buying a car? Check the engine compression.This is if of course you didn't check it prior to forking over multiple hard earned denominations. As I did not have the tester, nor was I in the country, this didn't work out beforehand.

Jumping quickly in, a tester cost about 2o GBP, another 5 for a 1o mm spark plug socket. Spark plug sockets are actually sold in the UK based on the thread size of the spark plug itself that screws into the head, not the actual nut that the socket turns, which is 16 mm. This shouldn't be confused with the larger spark plugs, having a thread size of 16 mm, and a nut size of much larger. These are huge.

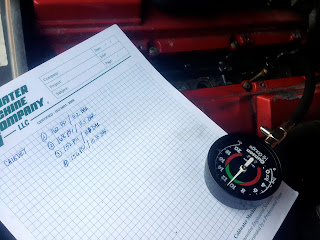

I performed this test on a cold engine in order to measure worst case, cranking 8-1o times at wot. The highest to lowest cylinder difference was 9.5%, average compression sitting right at 159.5.

Not bad at all!

For anyone checking compression on a cadet engine, the fuel pump fuse is in the engine bay fuse box. Remove this. Also disconnect the cam angle sensor from the front of the timing cover. This will prevent the engine from sparking and fueling but still enable the car to turn "on" and power the starter.

Since I removed all the spark plugs at once, laying the plug leads to the side outside of the head, the lack of cas connection specifically doesn't really matter when considering spark. I find it's easier and safer to uninstall all plugs, test all cylinders, and install all plugs rather than doing all 3 steps for each plug one at a time. If for some odd reason you wanted to test just one cylinder's compression, make sure to unplug the cas. You don't want the other 3 cylinders igniting any fuel in the engine via the other installed plugs, which would result in the engine actually starting at this inopportune time, as a partially open system on a reduced number of cylinders. This could possibly damage internal components, and at minimum sound awful and scare you unnecessarily during a simple compression test.

As the fuel injectors are still installed, pointed directly at the valves through the intake plenum runners, pull the pump fuse, shutting down any flow and subsequent pressure forcing fuel into the cylinders during the test <assuming an injector were activated and/or open>. Several cranks of fuel and no spark could easily flood cylinders causing start up issues or delay. In theory the injectors should not be firing because the cas is disconnected. We now have eliminated two controls for each condition, physically removing plugs for spark reduction, electrically isolating the fuel pump for fuel reduction, and unplugging the cas for both as the ecu needs this to know when to initiate spark and fuel, and won't otherwise.

In theory, if the injectors do open and the pump is not on, some fuel will gradually fall into the intake plenum as the rail may still have some fuel in it, some of which may make it into the engine. Surely not much will flow through during 1o seconds unpressurized, or even 1oo for that matter, and you have other issues if you are cranking it longer than that. If you are really paranoid as neither control on the fuel side is physical with respect to the injector, you could find the fuel and ignition relays and remove them, shutting down the entire circuit. This solution is similar to unplugging the cas, as it electrically shuts down the circuit, only this time downstream from the ecu. Even if the ecu wanted to pulse something, guessing without a cam angle reading, the signal wouldn't be able to get through. Lastly you could physically pull the injectors, but if you did this for a compression test I would personally call you crazy and point vigorously.

To put a nail in my tirade, I've done compression tests on several engines without disconnecting the cas, simply pulling all the plugs and removing the fuel pump fuse. It's just a simple, extra precaution that is a very easy step on most fuel injected engines, especially this one.

I'm amazed there are still 2oo's around that still have their stock air-boxes. Note the spark plug and coil pack bolts lining the engine bay side hood edge.

The cadet had a set of well looking Bosch Super Plus plugs, nothing to note. I didn't have a plug gapper to verify gap, nor was I replacing them at this time, so I just put them back in after the successful compression test.

Luckily I was able to reach the plugs with the short 3/8" extension. The wrench cleared the inner head webbing, but not the valve covers, so I had to watch out to keep from hitting them while breaking the plugs loose and re-torquing them.

Jumping quickly in, a tester cost about 2o GBP, another 5 for a 1o mm spark plug socket. Spark plug sockets are actually sold in the UK based on the thread size of the spark plug itself that screws into the head, not the actual nut that the socket turns, which is 16 mm. This shouldn't be confused with the larger spark plugs, having a thread size of 16 mm, and a nut size of much larger. These are huge.

I performed this test on a cold engine in order to measure worst case, cranking 8-1o times at wot. The highest to lowest cylinder difference was 9.5%, average compression sitting right at 159.5.

Not bad at all!

For anyone checking compression on a cadet engine, the fuel pump fuse is in the engine bay fuse box. Remove this. Also disconnect the cam angle sensor from the front of the timing cover. This will prevent the engine from sparking and fueling but still enable the car to turn "on" and power the starter.

Since I removed all the spark plugs at once, laying the plug leads to the side outside of the head, the lack of cas connection specifically doesn't really matter when considering spark. I find it's easier and safer to uninstall all plugs, test all cylinders, and install all plugs rather than doing all 3 steps for each plug one at a time. If for some odd reason you wanted to test just one cylinder's compression, make sure to unplug the cas. You don't want the other 3 cylinders igniting any fuel in the engine via the other installed plugs, which would result in the engine actually starting at this inopportune time, as a partially open system on a reduced number of cylinders. This could possibly damage internal components, and at minimum sound awful and scare you unnecessarily during a simple compression test.

As the fuel injectors are still installed, pointed directly at the valves through the intake plenum runners, pull the pump fuse, shutting down any flow and subsequent pressure forcing fuel into the cylinders during the test <assuming an injector were activated and/or open>. Several cranks of fuel and no spark could easily flood cylinders causing start up issues or delay. In theory the injectors should not be firing because the cas is disconnected. We now have eliminated two controls for each condition, physically removing plugs for spark reduction, electrically isolating the fuel pump for fuel reduction, and unplugging the cas for both as the ecu needs this to know when to initiate spark and fuel, and won't otherwise.

In theory, if the injectors do open and the pump is not on, some fuel will gradually fall into the intake plenum as the rail may still have some fuel in it, some of which may make it into the engine. Surely not much will flow through during 1o seconds unpressurized, or even 1oo for that matter, and you have other issues if you are cranking it longer than that. If you are really paranoid as neither control on the fuel side is physical with respect to the injector, you could find the fuel and ignition relays and remove them, shutting down the entire circuit. This solution is similar to unplugging the cas, as it electrically shuts down the circuit, only this time downstream from the ecu. Even if the ecu wanted to pulse something, guessing without a cam angle reading, the signal wouldn't be able to get through. Lastly you could physically pull the injectors, but if you did this for a compression test I would personally call you crazy and point vigorously.

To put a nail in my tirade, I've done compression tests on several engines without disconnecting the cas, simply pulling all the plugs and removing the fuel pump fuse. It's just a simple, extra precaution that is a very easy step on most fuel injected engines, especially this one.

I'm amazed there are still 2oo's around that still have their stock air-boxes. Note the spark plug and coil pack bolts lining the engine bay side hood edge.

The cadet had a set of well looking Bosch Super Plus plugs, nothing to note. I didn't have a plug gapper to verify gap, nor was I replacing them at this time, so I just put them back in after the successful compression test.

Luckily I was able to reach the plugs with the short 3/8" extension. The wrench cleared the inner head webbing, but not the valve covers, so I had to watch out to keep from hitting them while breaking the plugs loose and re-torquing them.

No comments:

Post a Comment