I'm a big fan of leaving things uncovered. If you spent that much time on something, designing, milling, cutting, welding, adjusting, show it off! I know this is a bit out of order, but I was in a rush to show shots of the engine back in the car, not to mention video of it running. This was yet another reason to take the engine back out after it came back from the fmic welder, one reason which amazingly enough, wasn't their fault.

The engine mounts started to show some rust around the edges, specifically near the welded joints. The camber plates and suspension columns are holding up nicely, but maybe they got more clear coat the first time around. They were also TIG welded as opposed to the thicker plate steel of the engine mounts which was stick welded. The transmission mount however had the same welding and no rusting, bringing me back to my excessive amount of clear coat solution.

I dipped them in the most toxic mix of chemicals I could come up with in an attempt to rid the surface rust that started to form over the last month.

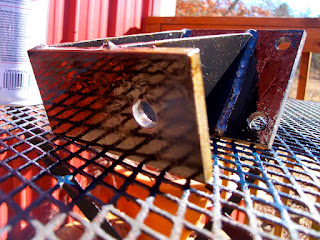

After a good soak, I scrubbed them with a stainless steel brush, focusing on the welded corners. Scratches appeared in the old clear coat. No, I promise they don't have leprosy, but once you start, you have to finish. After these in process pictures, I brushed and cleaned more, now removing the old clear coat as well in order to start from scratch.

KK sprayed on a thick fresh coat of clear, making sure to get all surfaces and edges.

Some if the initial patina shows where the stainless brush scratched the metal, but the rust is gone, and the mounts coated. Talk about having some character.

Re-installing was a snap, as was modifying the transmission mount one last time before installing. The car side tangs of the transmission cradle rubbed slightly after final assembly but were easily trimmed to clear. This was partially due to the previously mentioned transmission window cut debacle, and the re-settling of the transmission on the isolators as it was no longer semi-supported by the speedo sensor.

The engine mounts started to show some rust around the edges, specifically near the welded joints. The camber plates and suspension columns are holding up nicely, but maybe they got more clear coat the first time around. They were also TIG welded as opposed to the thicker plate steel of the engine mounts which was stick welded. The transmission mount however had the same welding and no rusting, bringing me back to my excessive amount of clear coat solution.

I dipped them in the most toxic mix of chemicals I could come up with in an attempt to rid the surface rust that started to form over the last month.

After a good soak, I scrubbed them with a stainless steel brush, focusing on the welded corners. Scratches appeared in the old clear coat. No, I promise they don't have leprosy, but once you start, you have to finish. After these in process pictures, I brushed and cleaned more, now removing the old clear coat as well in order to start from scratch.

KK sprayed on a thick fresh coat of clear, making sure to get all surfaces and edges.

Some if the initial patina shows where the stainless brush scratched the metal, but the rust is gone, and the mounts coated. Talk about having some character.

Re-installing was a snap, as was modifying the transmission mount one last time before installing. The car side tangs of the transmission cradle rubbed slightly after final assembly but were easily trimmed to clear. This was partially due to the previously mentioned transmission window cut debacle, and the re-settling of the transmission on the isolators as it was no longer semi-supported by the speedo sensor.

No comments:

Post a Comment